MANUFACTURING

& ENGINEERING

End-to-End High-Quality Solutions

From complex machined components to high-volume production fasteners – when you need custom-manufactured parts, we can quickly provide high-quality engineering solutions through one of nine Fastenal Manufacturing locations worldwide, including our Spensall facilities in Leeds, UK and Modrice, Czech Republic.

Our vertically-integrated operations span from design to delivery, including engineering support, secondary processes (heat treatment, coatings, etc.), and product testing – all executed internally to drive quality and lead time from your business.

WORDLWIDE RECOGNITION FOR QUALITY

MANUFACTURING & ENGINEERING SOLUTIONS

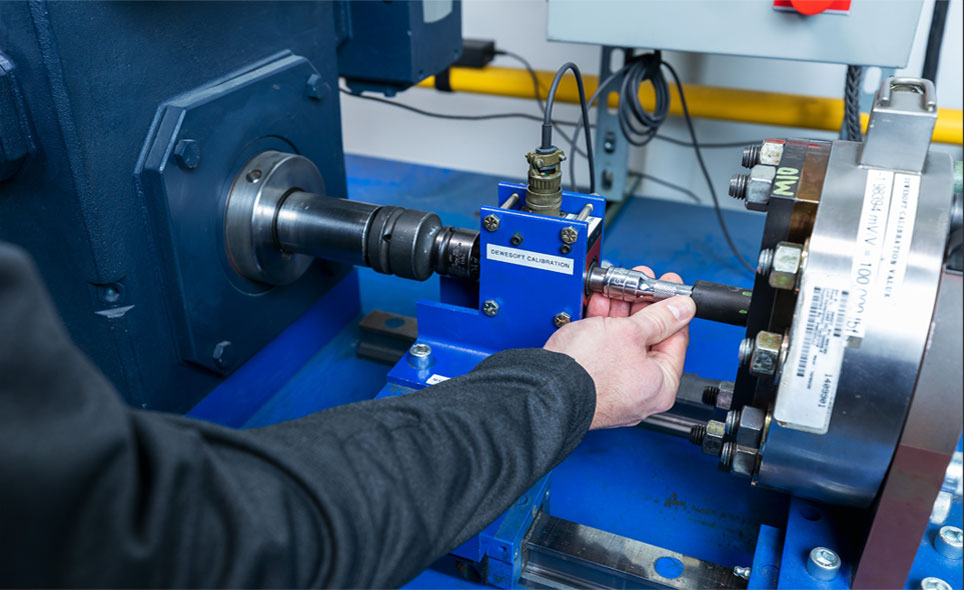

Engineering & Lab Services

- Dedicated PPAP team in Europe

- European Quality teams in UK and Czech Republic

- European Engineering team based in UK

- Technical Support & Resources

- Bolted Joint Design Analysis

- Fastener Failure Analysis

- On-Site Fastener Trainings

- Cost Savings Analysis

- Dimensional Testing

- Mechanical Testing

- Chemical Testing

- Fracture Analysis

- Nondestructive Testing

- Application Testing

9 A2LA Accredited Laboratories and 9 Manufacturing Locations

Our A2LA accredited testing laboratories are equipped to provide testing for Fastenal manufactured products as well as products supplied by Fastenal’s corporately approved suppliers. Product testing is conducted to internationally recognized standards including ASTM, SAE, ASME, ISO, and DIN as well as customer-specific standards and prints.

|

|

Spensall is an ISO 9001:2015 certified by TUV Rheinland of North America and OHS 18001:2007 accredited manufacturer with CNC and manual machining capabilities together with a range of support equipment to ensure a comprehensive service to our markets.

Three Core Fastenal Manufacturing Compentencies

Cold Forming

Cold forming through our Holo-Krome division

Hot Forged Bolting

High-integrity bolting through our Cardinal Fastener division

Precision Machining

Precision machining through out UK-based Spensall division

Industry Certifications

As an ISO 9001:2015 certified by TUV Rheinland of North America manufacturer, we maintain full traceability of raw materials and stringent quality control during each phase of production. With multiple ISO/IEC 17025 accredited labs, millions of dollars in testing equipment, and some of the most experienced operators, engineers and quality personnel in the industry, we don’t just produce parts – we produce perfection.

Standards & Certifications

- ISO 9001:2015 certified by TUV Rheinland of North America certified facilities (Manufacturing, distribution hubs and servicing branches)

- Nine ISO/IEC 17025 mechanical test laboratories, two in Europe (Czech Rep and UK)

- ISO 9001:2015 certified by TUV Rheinland of North America (all Fastenal Manufacturing locations)

- Three ISO/IEC 17025 labs within our manufacturing facilities (Winona, MN; Wallingford, CT; Czech Republic)

- NQA-1 & 10CFR50 Appendix B compliant

- Application Testing

Participation in 40+ Standards Committees

- British Standards Institute

- ISO committee TC2 European members

- IASTM International: 26 Subcommittees

- ASME: 18 Subcommittees

- ISO: Head of Delegation, TC2 Fasteners

- API: 11 Subcommittees

- NACE International

- AWHEEM & SPE

- SAE

- ASM

- RCSC